1、 Sk water ring vacuum pump product overview:

SK series water ring vacuum pump and compressor are used to pump or pressure gas and other non corrosive, water-insoluble and non-solid particles gas, so as to form vacuum or pressure in closed containers and meet the process requirements. A small amount of liquid is allowed to be mixed in the gas inhaled or compressed.

SK series water ring vacuum pumps and compressors are widely used in machinery, petroleum, chemical, pharmaceutical, ceramic, sugar, printing and dyeing, metallurgy and electronics industries.

Because in the working process, this kind of pump compresses the gas in the isothermal state, so it is not easy to cause danger when pressing or pumping flammable and explosive gas, so it is more widely used.

2、 Working principle of SK water ring vacuum pump:

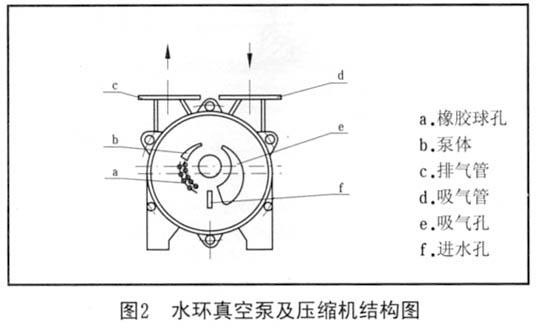

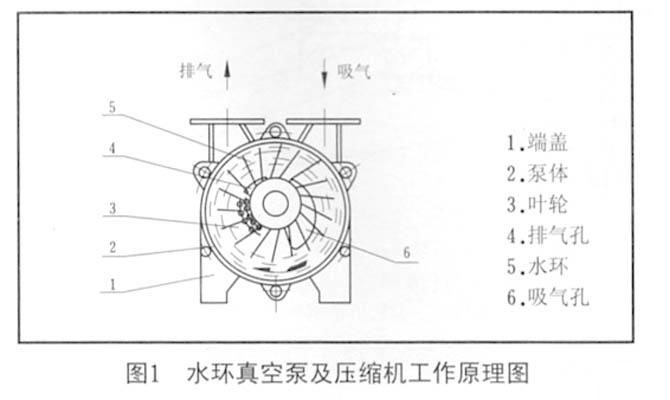

As shown in Figure 1, the impeller 3 is eccentrically installed in the pump body 2. Therefore, when the impeller 3 rotates, the water forms a rotating water ring 5 on the inner wall of the pump body under the action of centrifugal force. The upper inner surface of the water ring is tangent to the wheel hub and rotates in the direction of the arrow. During the first half of the rotation, the inner surface of the water ring gradually separates from the hub, so a closed space is formed between the impeller blades and the water ring In the second half of the revolution, the inner surface of the water ring is gradually close to the hub, the space between the blades is gradually reduced, and the space gas pressure is increased. When the pressure is higher than the exhaust port pressure, the gas between the blades is discharged, In this way, every time the impeller rotates, the space between the blades sucks and exhausts once, many spaces work continuously, and the pump continuously sucks or presses the gas.

Because in the working process, the work produces heat, which will make the working water ring heat, and at the same time part of the water and gas are discharged together. Therefore, in the working process, the pump must be continuously supplied with water to cool and supplement the water consumed in the pump to meet the working requirements of the pump.

When the gas discharged from the direct vacuum pump is no longer used, a gas water separator is connected at the exhaust end of the pump (which can be replaced by a water tank made by ourselves). After the waste water and part of the water are discharged into the gas water separator, the gas and water are separated, and the gas is wiped out by the wiping pipe, and the remaining water is supplied to the pump through the return pipe for further use. With the extension of the working time, the temperature of the working water will increase continuously. At this time, a certain amount of cold water (tap water) should be supplied from the water supply of the gas-water separator to reduce the temperature of the working water and ensure that the required technical requirements and performance indicators can be achieved.

When used as a compressor, the exhaust gas 11 of the pump is connected with a gas-water separator, and the gas-water mixture is automatically separated after entering the gas-water separator, The gas is transported to the required system by the exhaust pipe, and the working water is discharged automatically through the switch. When the gas is compressed, the working water is easy to heat up, and the water is discharged from the pump outlet, and the temperature will become higher. Therefore, at the bottom of the gas-water separator, cold water should be continuously supplied to supplement the discharged hot water, so as to ensure the performance of the compressor, Meet the technical specifications and process requirements.

Start up and stop

1. Start up:

The pump which has been shut down for a long time must be turned by hand for several weeks to confirm that there is no jamming or other damage in the pump. The start-up is carried out in the following order (see the equipment description diagram).

1) Close the gate valve 4 on the air inlet pipe;

2) Start the motor (from the transmission direction, the motor rotates clockwise, the right side is the suction port, and the left side is the exhaust port). Pump for mechanical seal, should first add water to the mechanical seal, and then start the motor;

3) Open the valve 6 on the water supply pipe or directly use tap water to supply water into the pump to gradually increase the water supply until the water supply meets the specified requirements;

4) When the pump reaches the limit vacuum or maximum pressure, open the valve 2 on the intake pipe, and the pump starts to work normally;

5) Adjust the packing gland to make the water drop outward;

6) The valve is used to adjust the water supply of the gas water separator to the pump, so as to operate under the required technical conditions, so as to minimize the power consumption, reach the performance index and meet the working requirements;

7) Adjust the water quantity supplied by water supply pipe to gas water separator, so as to use the minimum water consumption and ensure the technical specifications required in the pump;

8) When the pump works under the limit pressure, the explosion sound may occur in the pump due to physical action, but the power consumption does not increase. The valve on the intake pipe can be opened to let a small amount of gas enter into the pump, and the explosion sound will disappear. If the explosion sound does not disappear and the power consumption increases, it indicates that the pump has failed and should be stopped for maintenance.

Parking should be in the following order:

1) Close the valve on the intake pipe (for compression, close the valve on the exhaust pipe first, and then close the suction valve);

2) Close the gate valve on the water supply pipeline. Do not stop the pump immediately after the water supply is stopped. Keep the pump running for 1-2 minutes to discharge part of the working fluid. The pump is a mechanical seal, and the cooling water of the mechanical seal cannot be closed;

3) Turn off the motor, and then turn off the mechanical seal cooling water;

4) Rust and pump must be shut down for more than a day if water will drain away.

3、 Sk water ring vacuum pump maintenance:

1. Check the operation and lubrication of bearings regularly.

2. The normal working bearing temperature is 15 ℃ - 20 ℃ higher than the surrounding temperature, and the maximum allowable temperature is 55 ℃ - 60 ℃: the normal working bearing should be filled with oil 3-4 times a year. Clean the bearing at least once a year and replace the lubricating oil.

3. If it is a packing seal, the packing should be compressed regularly. If the packing cannot guarantee the required sealing performance due to wear, the new packing shall be replaced. Do not over press the packing. Normally compressed packing allows water to drip out to ensure cooling and strengthen sealing.

If the mechanical seal is used and leakage occurs, check whether the dynamic and static rings of the mechanical seal have been damaged, or the sealing ring has been aged. In case of the above situation, new parts shall be replaced.

Disassembly and assembly

disassemble:

The disassembly of the pump is divided into partial disassembly and inspection, complete disassembly, repair and replacement of parts. Before disassembly, the water in the pump cavity should be drained, and the air intake and exhaust should be removed. In the process of disassembly, all pads should be carefully removed. In case of damage, new pads with the same thickness should be abstracted during assembly. The pump should be disassembled from the rear end (end without coupling) in the following order:

1) loosen and remove the two connecting pipes (sk-1.5/3 has no connecting pipes);

2. Loosen and remove the rear bearing gland;

3. Loosen the round nut with hook spanner and remove the packing gland;

4. Loosen the nut of packing gland and remove the packing gland

5. Loosen the connecting bolts between the pump body and the end cover and the accumulated bolts at the pump foot; v 6 add a support under the pump body, and then remove the end cover from the shaft;

7 remove the pump body. The part of the pump has been disassembled so far. At this time, the working part of the pump and each inlet part can be inspected and cleaned. Complete disassembly shall be carried out in the following order;

8. Loosen the other pump foot bolt and remove the pump head from the base;

9 remove the coupling;

10 remove the key of the coupling from the shaft;

11 remove the front bearing gland;

12. Loosen the back cap of the bearing and take down the bearing frame and bearing;

13. Loosen the compression nut of the packing gland and remove the packing gland;

14 take the shaft and the blade out of the end cover together;

15 remove the shaft sleeve from the shaft;

16 take impeller from shaft.

After disassembly, the fitting surface and thread should be cleaned and coated with engine oil.

Assembly:

① Before assembly, clean the gasket left on the fitting surface and wipe it carefully

② Remove the old oil from the bearing and bearing frame and replace it with new oil:

③ The assembly sequence is opposite to the disassembly sequence.

During assembly, the most important thing is to adjust the clearance between the impeller end face and the disk on the end cover. The size of the clearance directly affects the performance of the pump. The total clearance on both sides is specified in the table below, which is obtained by adding a cushion between the pump body and the end cover. The clearance between the two ends of the impeller should be uniform. The shaft sleeve or back cap can be tightened to move the impeller to adjust.

4、 Description of SK water ring vacuum pump:

SK series water ring vacuum pump and compressor system consists of vacuum pump (press), coupling, motor, gas water separator and bamboo road.

The working process of vacuum pump, compressor and gas water separator is as follows: the gas enters the vacuum pump or compressor through the pipeline through the valve, and then discharges into the gas water separator through the gas guide pipe, and is discharged through the exhaust pipe of the gas water separator. When used as a press, the gas water mixture discharged by the compressor is in the water separator. The gas is transported to the system where the gas is to be pressurized through Langmen, while the water is left in the gas water separator. In order to keep the water level of the gas water separator constant, an automatic overflow switch is installed, When the water level is higher than the required water level, the overflow switch is opened. Water overflows from the overflow mark: when the water level is lower than the required water level, the overflow switch is closed, and the water level in the gas-water separator rises to the required level. The working water in the vacuum pump or pressure machine is supplied by the gas-water separator (tap water can also be used). The size of the water supply tray directly affects the performance of the vacuum pump, so it is fed from the water supply pipe Valve.

The difference between gas suction system and pressure feed system is only due to the internal structure of gas water separator. When pumping gas, the suction pressure is lower than atmospheric pressure, while the exhaust pressure is equal to atmospheric pressure. There is only overflow pipe in the gas water separator: when the gas is compressed, the suction port is under normal pressure (or vacuum state), and the outlet pressure? Is at one atmospheric pressure. In order to ensure the gas pressure, the water level of the gas water separator is controlled by the overflow switch.

equipment installation

1. Installation of pump and motor:

Before installing the vacuum pump and compressor, rotate the coupling by hand to confirm whether there is jamming or other damage in the pump. When the whole set of equipment arrives at the installation site, the package has been damaged or the pump is subject to moisture during storage, and the pump is installed again six months after delivery, it should be completely disassembled for inspection and repair before installation. If the vacuum pump or compressor operates normally, install the pump on the pump seat. Before the motor is fixed on the pump seat, the concentricity of the motor shaft and the pump shaft should be corrected, because even a small inclination between the motor and the pump shaft will cause bearing heating and serious wear of parts. The required concentricity (as shown in the figure) is achieved when the straight edge is placed parallel to the coupling, and there is no gap at any position of the whole circumference and the axial clearance of the coupling is equal.

2. Installation of gas water separator:

The gas water separator is installed on the foundation according to the outline drawing.

If it is necessary to change the installation position, it should be noted that the connecting pipeline between the separator and the pump should not be too long and the turning should not be too fast, otherwise the flow loss of the gas water mixture in the pipeline will increase, which will increase the exhaust resistance, thus reducing the flow and vacuum degree and increasing the power consumption.

The air inlet flange of the gas-water separator is connected with the pump exhaust flange by a elbow. At the bottom of the gas-water separator, there is a pipeline connected with the pump to supply the water required for the normal operation of the pump. The water supply is regulated by the valve on the pipeline. There is another pipeline for the gas-water separator, and the valve is installed on the pipeline to supplement the working water consumed.

3. Pipeline installation between pump and gas water separator:

The exhaust pipe of the vacuum pump or press is connected with the intake pipe of the gas water separator. When used as a compressor, the exhaust pipe of the gas water separator is connected with the system using compressed gas. Generally, the pipeline shall not be too long and the turning shall not be too fast. When used as a vacuum pump, the gas is discharged from the exhaust port of the gas water separator to the atmosphere. In order to improve the working environment, the gas can be discharged out of the working place through the pipeline.

The flange joint of the pipeline should be sealed with gasket, especially if the air inlet of the pump is not tight, the vacuum degree can not be reached.

A reservoir valve should be installed on the intake pipe of the vacuum pump or press, so that it can be closed first when the pump is stopped, so as to prevent the water in the vacuum pump or press in the exhaust pipe

Return to the system under pressure. In order to facilitate the work, it is better to install a vacuum meter between the air inlet and the valve, so as to check whether the vacuum is working normally at any time. When it is used as a compressor, a gate valve should be installed on the exhaust pipe of the gas water separator (the one-way valve is preferred to ensure that the gas will not return and the working water will return to the system in case of abnormal conditions). A pressure gauge should be installed between the exhaust pipe and the valve to check whether the pressurized gas reaches the required pressure.

In addition, attention: the pipeline should be equipped with a fine screen filter device (the hole is not greater than 0.5mm) to prevent impurities from entering the pump and causing damage to the pump.

4. Adjustment structure:

SK series water ring vacuum pump is used to adjust the vacuum degree and flow rate with the valve installed on the intake pipe. In any form, the valve is installed on the exhaust pipe to regulate the pressure of the compressed gas. When the compressed gas is not allowed to be discharged according to its service conditions, an air duct should be installed between the exhaust pipe and the exhaust pipe, and its diameter is the same as that of the valve installed on it, so as to adjust the gas volume to a large extent

Sk water ring vacuum pump

Widely used in machinery, petroleum, chemical, pharmaceutical, ceramics, sugar, printing and dyeing, metallurgy and electronics industries.